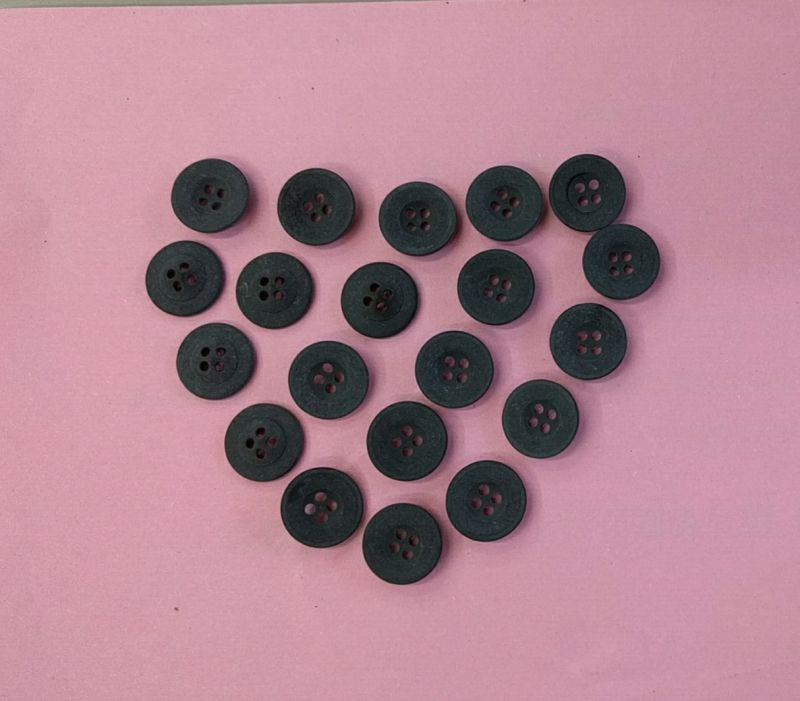

The secret weapon of low-key luxury-the charm of electrophoresis technology

Behind this seemingly inconspicuous little button lies a high-tech secret-electrophoresis. It is this technology that gives the button a unique matte black appearance, while giving it excellent corrosion and scratch resistance. Each button has gone through multiple complex processes to ensure that the surface is even and delicate, and the hand feels soft while retaining a strong metallic texture. Such superb technology not only improves the quality of the button itself, but also makes it an indispensable part of high-end clothing.

Details determine success or failure: the advantages of webbing buttonhole design

In addition to the unique charm of the appearance, this button is also functional. Its webbing buttonhole design cleverly solves the problem of caton or wear that may exist in traditional buttons, making it smoother to wear and take off. Not only that, this design can also be easily adapted to fabrics of various thicknesses, whether it is light silk or heavy wool, it can be perfectly matched, providing designers with great flexibility and convenience.

The Art of Materials: Why Resin over Traditional Metals?

Compared with common metal buttons, this one is made of high-performance resin material. The advantages of the resin are obvious: it is lighter and will not cause skin discomfort due to long-term wear; more importantly, the resin has natural antioxidant properties, even after years of use will not appear rust mottling phenomenon. Therefore, it can be said that this button is not only a one-time consumable, but also a classic that can accompany for a long time.

From Factory to Closet-The Rigorous Process Behind Production

A real high quality button is not made overnight, but requires a series of rigorous tests and fine polishing. First of all, the raw materials are selected and screened, and then sent to professional equipment to complete the preliminary molding task; the next step is the most critical step-through the advanced electrophoretic coating production line to firmly adhere to the specific coating on the substrate, and repeated testing until the indicators have reached the predetermined standard. The whole process is closely linked, and any problem in any link will be eliminated immediately, only to bring the most satisfactory product experience to consumers.

with infinite inspiration: suitable for all kinds of occasions of classic single product

Whether you are a professional elite or a street trendsetter, or a bride who pursues romantic dreams, such a classic and versatile button can always find its own stage. It can be hidden in the inner cuffs of a straight suit to add a touch of composure; it can also be boldly exposed to the front zipper of the jacket to create a casual cool atmosphere; of course, in the white wedding dress with a few such black elements, it will instantly break the monotonous pattern and inject a mysterious charm ...... The possibilities are endless and only need to be explored.

Customize Your Unique Logo-Introduction to Personalized Services

In order to enable each customer to have a unique work to express their own opinions, we have specially launched a customized option service. You can put forward specific requirements such as engraving brand Logo patterns or adjusting size specifications according to your preferences. We will carefully create finished products that meet the full marks of all imagination space expectations and give them back to you according to the instructions! From now on, you don't have to worry about bumping shirts anymore ~